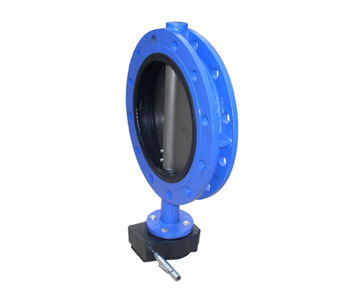

Butterfly valve operates on simple structures. They can be used for low-pressure piping. It achieves the opening and closing function by turning a closing piece, around a shaft throughout the top to the bottom of it. Butterfly valves are mostly used to control the flow of various types of fluids, including air, water, steam, slurry, oil, liquid metals and radioactive media. It is mainly composed of valve body with a circle shape in the middle, stem/shaft, disc and seat (seal ring) built in the body.

Type of butterfly valves

Lug Type Butterfly Valve

Wafer Type Butterfly Valve

Gear Operated Butterfly Valve

Grooved Butterfly valve

Lever Operated butterfly valve

Manual Butterfly Valve

dual-plate-wafer-type-check-valve

U-Type Butterfly valve

Butterfly Valves Dimensions and Info

Dimension | 11/2″-48″ |

End Connection | wafer type, lug type, double flanged, U-section, grooved end |

Body Material | gray iron(GG25), ductile iron(GGG40/50), cast steel(WCB), stainless steel(CF8,CF8M,CF3,CF3M) |

Disc Material | ductile iron(Nickle plated or nylon coated) cast steel(A216WCB) stainless steel(CF8,CF8M,CF3,CF3M) aluminum bronze(C954) |

Seat Material | EPDM, Buna-N(NBR),PTFE, viton, metal seated |

Stem material | SS410,SS416,SS304, SS316 |

Actuator | handle lever, worm gear, pneumatic actuator, chain operator |

Standard | API 609, BS5155, MSS SP-67/68, EN593 |

Advantages of Butterfly Valves

- Easy to open and close fast, labor-saving, small fluid resistance.

2. Appropriate for slurry

- Simple structure, short structure length, small size, light weight, whiles suitable for large diameter valves.

- Small fluid resistance when operating at full open condition, thus high flow speed can be achieved.

- At low pressure, it achieves good sealing.

- Decent adjustment capability.

- Easy installation.

- Small opening and closing torque.

- Good sealing performance at low pressure.

- Flexible operation options, involving manual, electric, pneumatic, hydraulic mode.